In today’s competitive market, advertising plays a crucial role in promoting products and services. As businesses strive to capture the attention of their target audience, advertising led screen suppliers have emerged as key players in providing innovative solutions for effective marketing campaigns.

The Role of Advertising LED Screen Suppliers

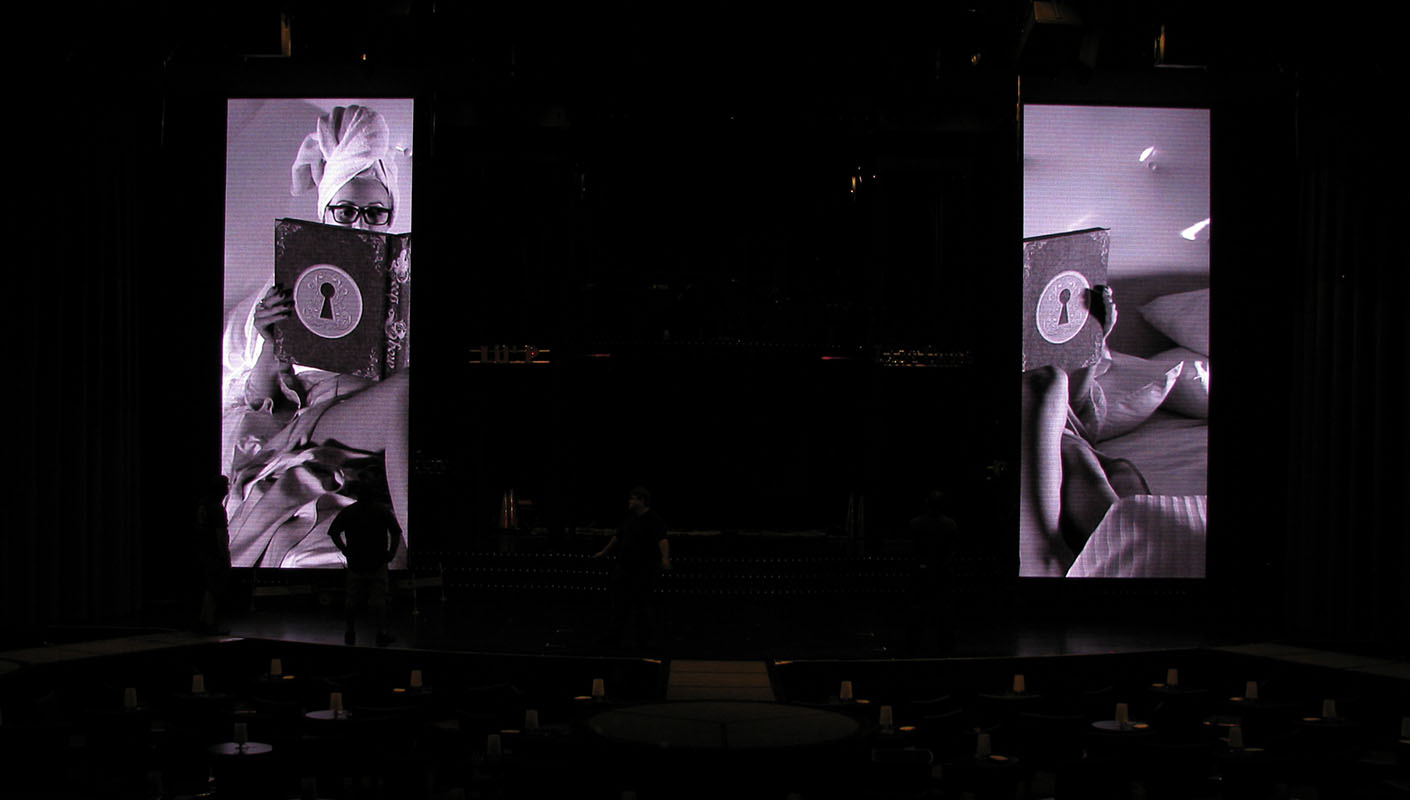

Advertising LED screen suppliers offer a wide range of high-quality display screens that are specifically designed for outdoor advertising purposes. These suppliers understand the importance of captivating visuals and eye-catching displays to attract potential customers. By utilizing advanced technology and creative designs, they provide businesses with powerful tools to convey their messages effectively.

Moreover, advertising LED screen suppliers offer customizable options that cater to different business needs. Whether it is a large-scale billboard or a smaller digital signage solution, these suppliers can tailor their products to fit specific requirements. This flexibility allows businesses to create unique and impactful advertisements that resonate with their target audience.

The Impact of Sports LED Display

Sports events draw massive crowds and present an excellent opportunity for businesses to reach a diverse audience. Advertising LED screen suppliers recognize this potential and have developed sports-specific displays that enhance the spectator experience while providing valuable promotional opportunities.

sports led displays are strategically placed within stadiums or arenas, ensuring maximum visibility for both attendees and viewers watching from home. These dynamic screens showcase live action replays, player statistics, sponsor advertisements, and engaging content during breaks in play. By partnering with advertising LED screen suppliers specializing in sports displays, businesses can effectively engage fans while increasing brand exposure.

The Innovation by Retop

Retop is one such leading supplier in the field of advertising LED screens known for its commitment to innovation and customer satisfaction. With years of industry experience under its belt, Retop has consistently delivered cutting-edge solutions that meet the evolving demands of businesses.

Retop’s range of advertising LED screens boasts exceptional image quality, durability, and energy efficiency. Their products are designed to withstand various weather conditions, ensuring uninterrupted visibility for advertisements throughout the year. Additionally, Retop offers comprehensive technical support and maintenance services to ensure optimal performance and longevity of their displays.

Conclusion

In conclusion, advertising LED screen suppliers play a vital role in helping businesses effectively communicate their messages to target audiences. With customizable options and innovative solutions like sports LED displays offered by companies such as Retop, businesses can create impactful marketing campaigns that capture attention and drive results. By embracing these advancements in advertising technology, businesses can stay ahead in today’s competitive market.